By: Hilary Thesmar, PhD, RD, FMI Vice President, Food Safety Programs, Food Marketing Institute

Product tracing used to be something we needed when things went wrong – when there was a recall or a food safety investigation. But now, product tracing has gone mainstream and has benefits well beyond food safety. Surprised?

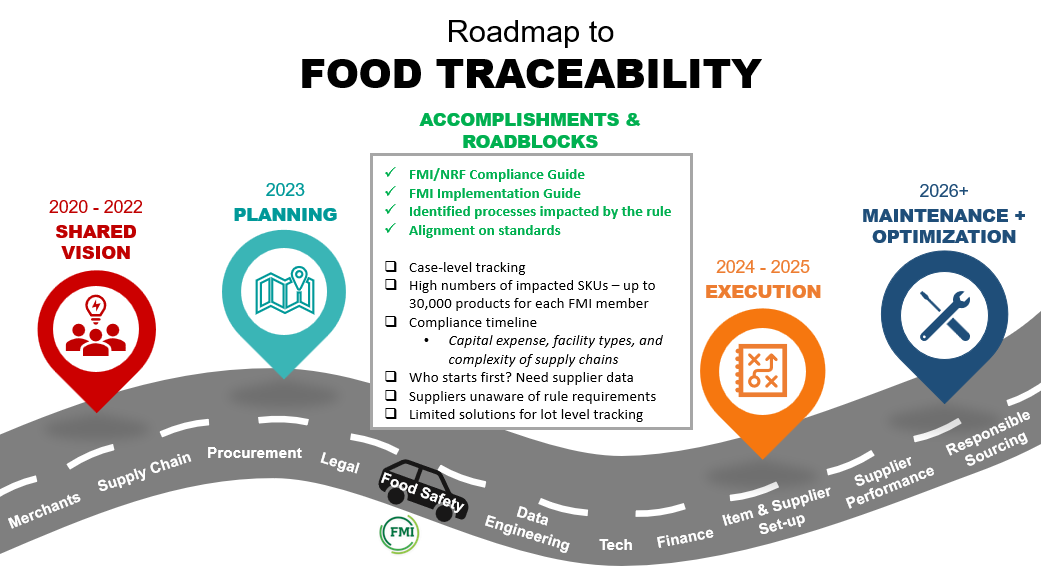

Many elements of traceability have existed for a while, but it has not been until recently that the need for implementation of effective traceability systems went beyond the one step forward and one step back requirement of the Bioterrorism Act of 2002. An industry shift, with a greater focus on traceability can be attributed to a number of reasons to include, but not limited to: an increased demand from consumers for transparency; the desire to minimize food waste by optimizing operational efficiency; strengthening food safety programs to identify products in the event of a crisis; a shift in the regulatory environment, etc.

The Global Food Traceability Center defines traceability as the “ability to access any or all information relating to a food under consideration, throughout its entire life cycle, by means of recorded identifications.” Traceability is more than just good data; it is the ability to link data throughout the supply chain so that at any point information can be accessed in order to achieve greater supply chain visibility.

The benefits of traceability systems are often dependent on a specific company. A recent Comprehensive Reviews in Food Science and Food Safety article, Assessing the Value and Role of Seafood Traceability from an Entire Value-Chain Perspective, identified the following as the top seven benefits a business gains from traceability systems:

- Increase quality

- Improve product recalls

- Improve inventory tracking

- Improve food safety

- Improve customer service

- Respond to consumer demand

- Verify harvest date and location

These benefits of traceability were further grouped into the following three benefit categories: drive company-level efficiencies, provide company-level competitive advantages, and mitigate market and operational risks faced by the firm.

So if your company is thinking about implementing a traceability system the following considerations should be made:

- The vision of the company and the direction your company is heading.

- Identify the need for traceability within your company.

- What benefits are desired from implementing a traceability system?

- Know your suppliers. Evaluate relationship with supply chain partners and gain buy-in.

- Availability of key data elements.

- Appropriate technology to assist with both forward and backward information sharing.

Successful implementation of a full traceability system heavily depends on a company’s willingness to share information and engage in a two-way conversation with supply chain partners. Often companies are hesitant to implement full visibility, which may be due to many factors the primary one being the proprietary nature of the supply chain. For this reason, FMI has partnered with ReposiTrak® to offer solutions for retailers and food companies. ReposiTrak® is a technology that:

- Is interoperable with any system and can accept or generate information in any format;

- Doesn’t require a standard code to identify an item or a location, but can easily use them if they are available;

- Can authenticate and verify the participant or the product at a specific node in the supply chain;

- Has information available if necessary but protects the confidentiality of the supply chain; and

- Is a low cost solution requiring no hardware purchase and no software install, and it’s ready now with over a decade and a half of experienced use.

Traceability is an important business and food safety tool that will help you identify where your products are, how much you have and streamline your inventory control. Having control over your supply chain is critical on a daily basis and during a crisis.

Industry Topics address your specific area of expertise with resources, reports, events and more.

Industry Topics address your specific area of expertise with resources, reports, events and more.

Our Research covers consumer behavior and retail operation benchmarks so you can make informed business decisions.

Our Research covers consumer behavior and retail operation benchmarks so you can make informed business decisions.

Events and Education including online and in-person help you advance your food retail career.

Events and Education including online and in-person help you advance your food retail career.

Food Safety training, resources and guidance that help you create a company food safety culture.

Food Safety training, resources and guidance that help you create a company food safety culture.

Government Affairs work — federal and state — on the latest food industry policy, regulatory and legislative issues.

Government Affairs work — federal and state — on the latest food industry policy, regulatory and legislative issues.

Get Involved. From industry awards to newsletters and committees, these resources help you take advantage of your membership.

Get Involved. From industry awards to newsletters and committees, these resources help you take advantage of your membership.

Best practices, guidance documents, infographics, signage and more for the food industry on the COVID-19 pandemic.

Best practices, guidance documents, infographics, signage and more for the food industry on the COVID-19 pandemic.